2025-04-26Source:

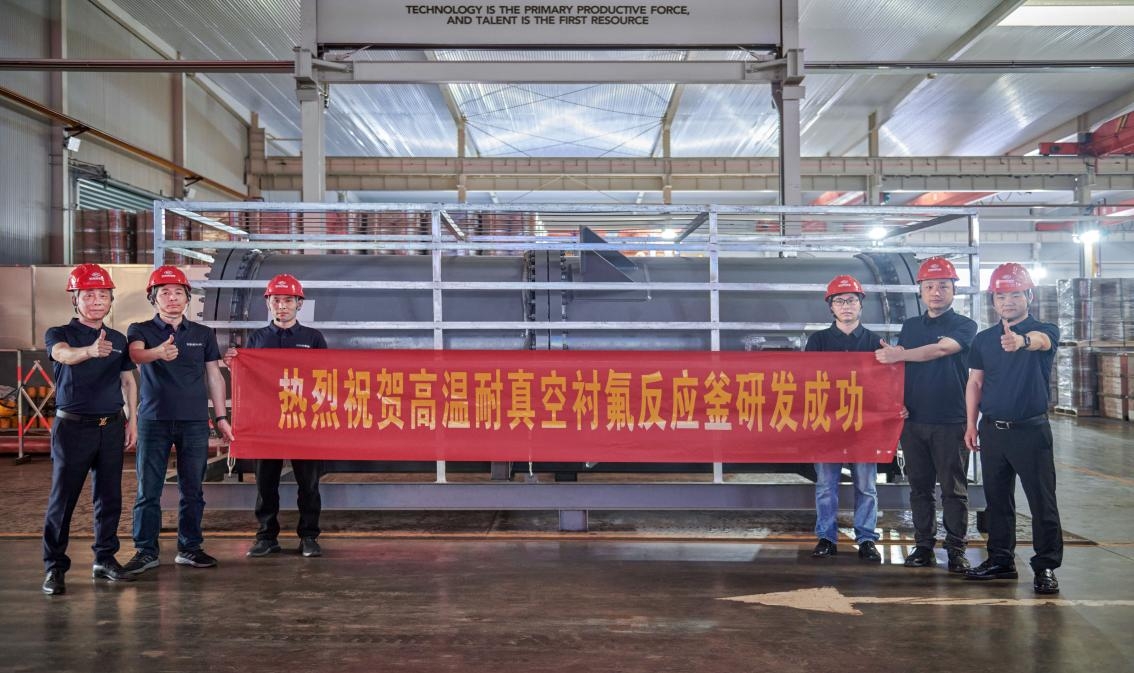

NFL's self-developed ultra-clean, high-temperature-resistant, fully-vacuum fluorine-lined reactor has been successfully manufactured and delivered. This milestone not only showcases the company's leap in high-end chemical equipment technology but also elevates NFL's application solutions for food-grade phosphoric acid concentration to new heights.

Since the project was launched, the equipment has focused on the actual process requirements of the food processing and high-purity phosphoric acid concentration industries, and has conducted in-depth research and development for complex working conditions such as high temperature, high acid concentration, high negative pressure, and high cleanliness. Focusing on the three core indicators of "safety, stability, and adaptability", it fully demonstrates the technical depth of NFL in the field of high-end chemical equipment design and manufacturing, and has obtained the invention patent for this.

The equipment adopts a composite structure of Q245R carbon steel matrix + PTFE lining, which combines the high strength of carbon steel with the excellent chemical stability of PTFE, and has excellent corrosion resistance. The PTFE lining material meets the requirements of FDA, EHEDG and 3A biological clean equipment, and is safely applicable to food-grade phosphoric acid concentration processes with acid concentrations ≥ 85%.

The special process makes the steel body and PTFE lining seamlessly and tightly combined, giving the equipment excellent corrosion resistance, negative pressure resistance and self-lubricating properties, and it can operate stably even in harsh working conditions. Its steel skeleton structure not only effectively shares the stress of the lining layer under negative pressure, but also can accurately control the thermal expansion and contraction of fluorine materials under high temperature conditions, ensuring the long-term and stable operation of the equipment.

Each device has passed the rigorous testing of the full vacuum real-time high temperature test platform and strictly follows the HG/T 4088 industry standard to ensure stable operation under various complex working conditions. The equipment is designed to have a pressure range of -0.1 to 1.6 MPa, is compatible with both vacuum and positive pressure modes, has a capacity of 30 m3 and supports on-demand non-standard customization, and has an inner lining roughness controlled at Ra≤0.8 μm, fully meeting the high standards required for food-grade applications.

Towards high-end intelligent manufacturing, empowering industry development